Quality Inspection Capability

At WellCare, quality is the cornerstone of our brand. With 15 years of deep expertise in the smart wearable industry, we adhere to a “full-process quality management” philosophy, integrating rigorous quality control into every stage—from supplier selection to after-sales service. We are committed to providing reliable, durable, and precise health monitoring devices for our global partners and users.

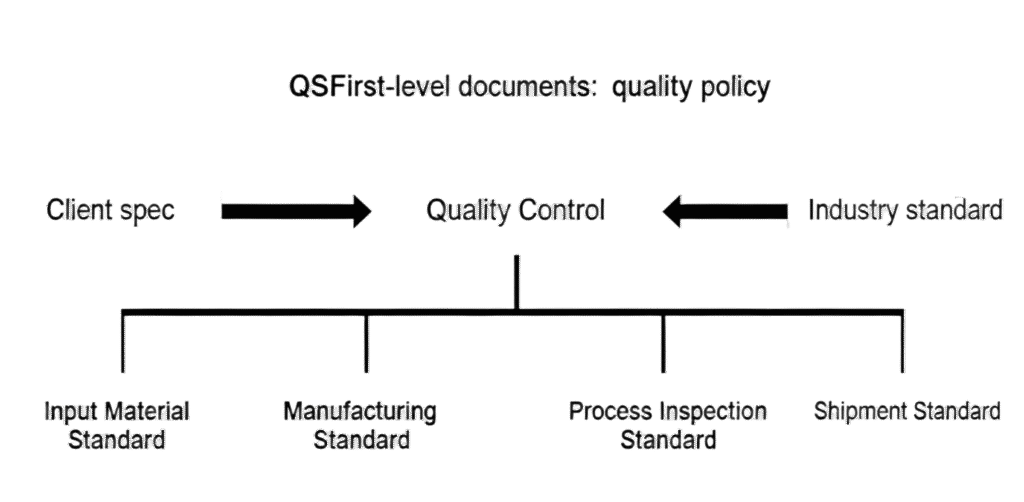

Quality Management Policy

Supplier Collaboration and Risk Management

Sign formal quality assurance agreements with all suppliers, requiring components to meet yield standards, reserving the right to reject non-compliant products, and holding suppliers accountable for related losses.

Promote environmental sustainability by signing eco-compliance agreements with suppliers, ensuring all components meet international environmental regulations such as EU RoHS and REACH, thereby helping customers meet stringent global environmental requirements.

Cultivate long-term, mutually beneficial partnerships. Since our founding, we have maintained stable collaborations with core suppliers, guaranteeing component quality and supply stability.

End-to-End Quality Management System

We have established a comprehensive quality management system supported by four core teams to achieve full-cycle quality oversight:

- R&D Quality Team: Responsible for quality planning during product development, conducting reliability testing and risk assessments for hardware, software, and algorithms to build a solid foundation for quality from the design stage.

- Testing Team: Leads software and hardware quality acceptance, rigorously validating product functionality, accuracy, and performance prior to mass production to ensure no design defects.

- Quality Assurance Department: Focuses on enhancing delivery quality through sampling and full inspections of finished products, ensuring non-conforming items never leave the factory.

- Quality Management Department: Continuously optimizes the company’s quality system, collects customer feedback, and drives iterative improvements in product quality and customer satisfaction.

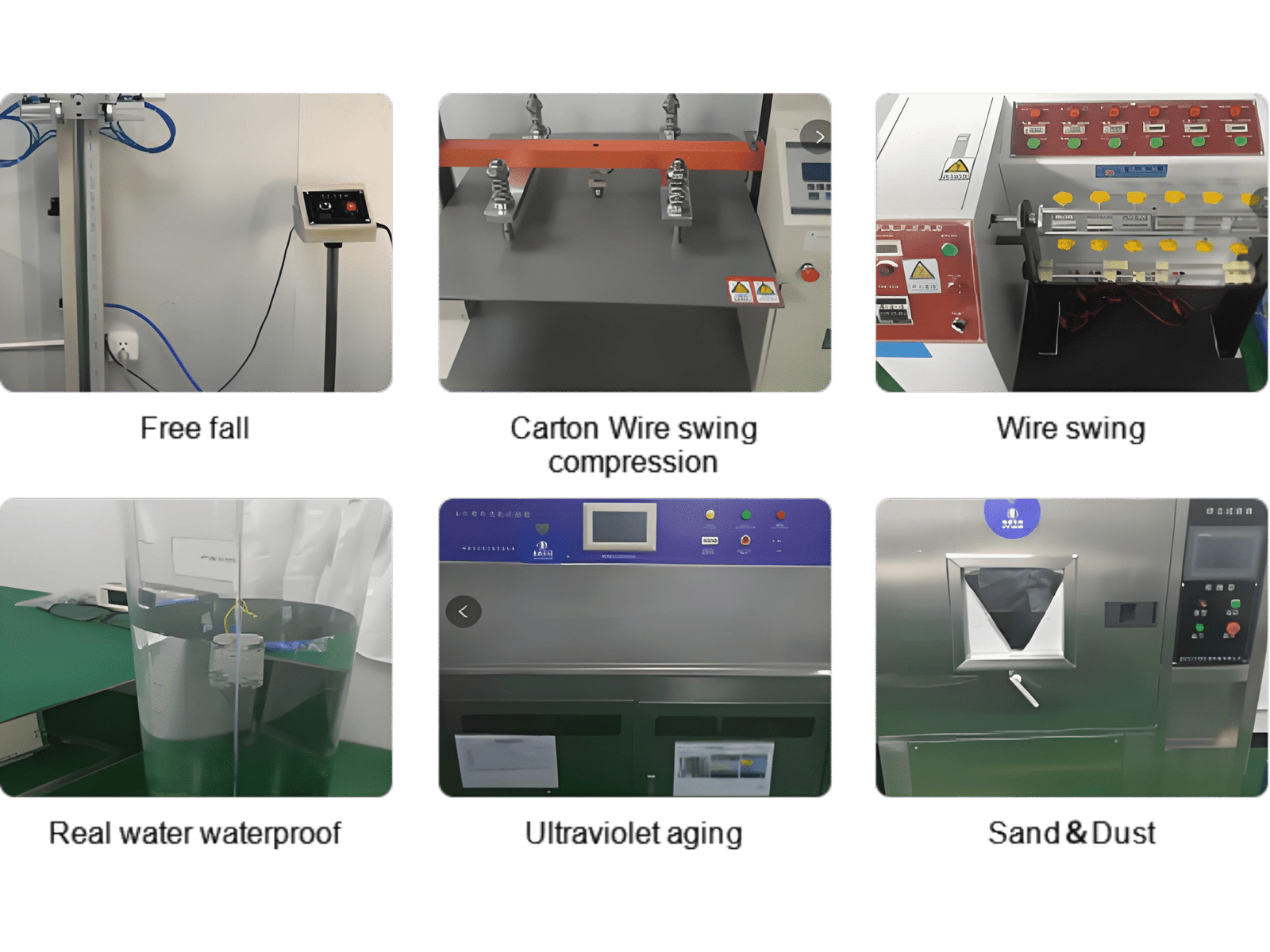

Environmental Adaptability Testing

Each product undergoes rigorous environmental testing to ensure stable performance across diverse usage scenarios:

- UV testing: 8 hours of light exposure + 4 hours of condensation, cycled 6 times

- Constant temperature and humidity testing: Stable operation within -30°C to 70°C and 93% relative humidity

- Electrostatic discharge testing: Withstands ±8KV air discharge and ±4KV contact discharge

- Salt spray testing: Immersion in 5% salt solution at 35°C for 48 hours

- Dust Resistance Test: Exposed to talcum powder environment (2kg/m³, particle size <75μm) for 8 consecutive hours

- Thermal Shock Test: 24 cycles between 70°C and -30°C environments, each lasting 1 hour

- Water Resistance Test: Complies with IP67 standard, supporting 30-minute immersion at 1 metre depth; additionally withstands 30-minute immersion in 80°C boiling water

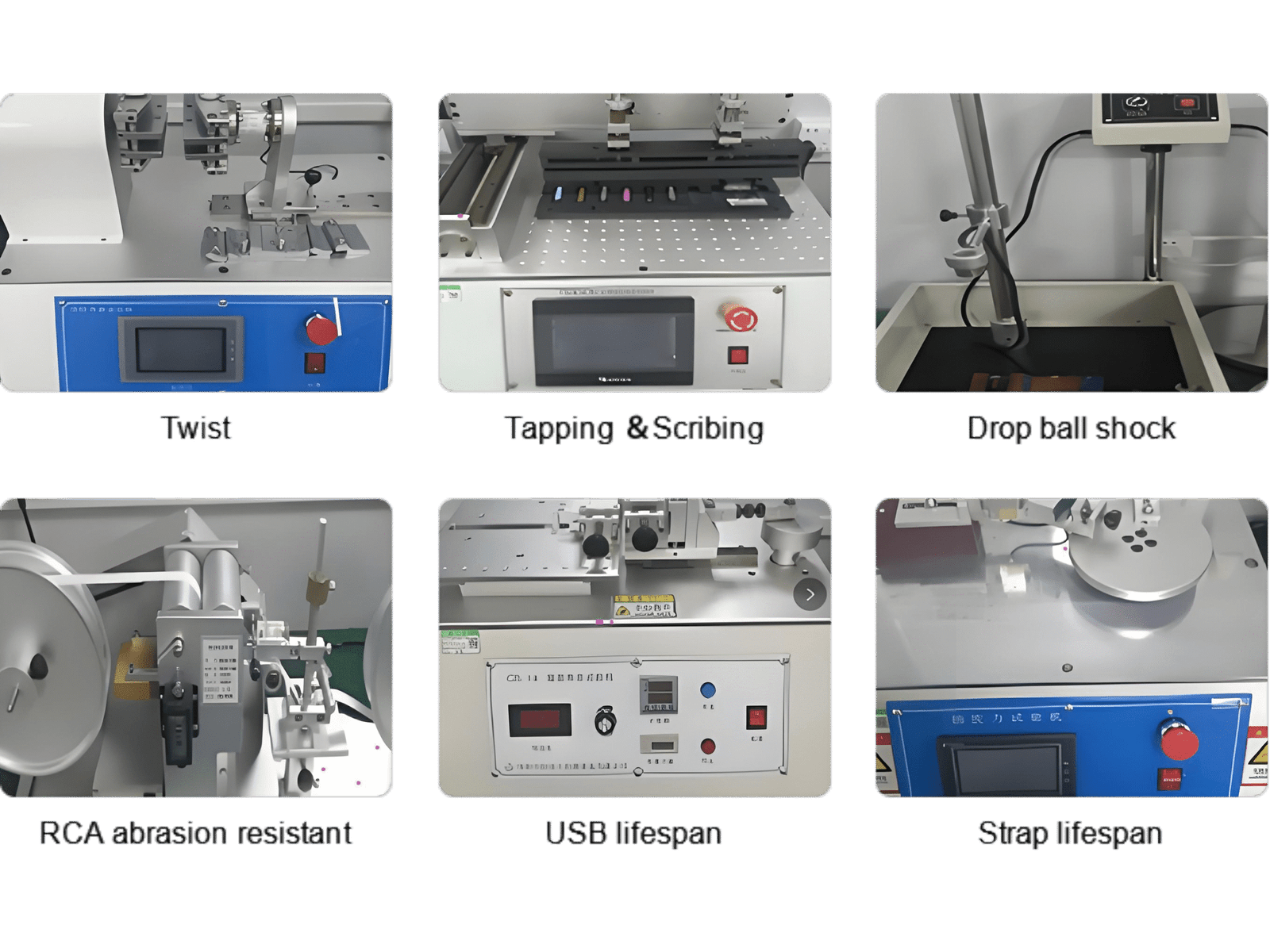

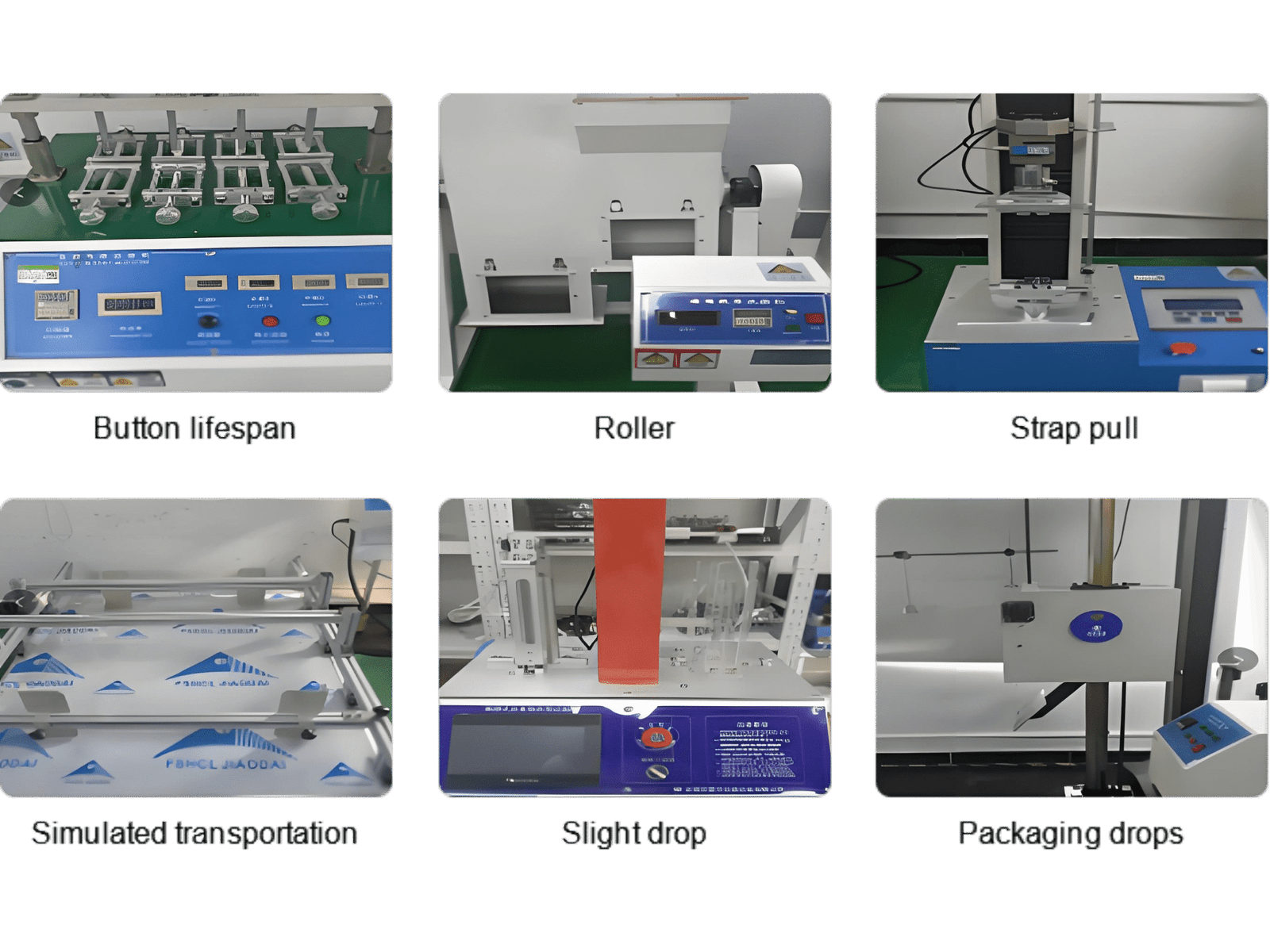

Mechanical and Durability Testing

Focusing on product durability and practicality, we conduct high-intensity testing simulating long-term usage scenarios:

Packaging and Transportation Testing:

- Free Fall Test: 1.2-meter height, 6 surfaces, 2 cycles

- Tumble Test: 1-meter distance, 100 cycles (200 rotations)

- Vibration Test: Frequency 2.5Hz, Amplitude 22mm, 110 cycles/minute

- Packaging Drop Test: 1-meter height, 6 faces + 1 corner + 3 edges

Component Durability Testing:

- Button Life Test: 50,000 presses at 4-6N force

- Strap Tensile Test: Withstands ≥8kg force, 2 tests

- Screen Tap Test: 100,000 taps at 250g force

- Charging Port Test: 2000 insertion/removal cycles

- Cable Swing Test: 300g load, ±60° swing for 2000 cycles

- Ball Drop Impact Test: 32g steel ball dropped from 0.5m height, 2 impacts

- Micro-Drop Test: 7cm height, 5000 drops in forward and reverse directions

IT Foolproofing Mechanism

Integrating intelligent foolproofing into production and testing processes, utilising automated testing equipment and software verification tools to prevent human error. Core components are assigned unique identification codes, enabling full-process traceability and rapid root cause identification for quality issues.

After-sales Care

- All products come with a one-year warranty, offering complimentary repairs or replacements for non-human-induced damage; core components benefit from an extended two-year warranty.

- Low Return Rate Assurance: Thanks to stringent quality control, customer returns due to functional defects consistently remain below 1%.

- Professional After-Sales Support: Dedicated Field Application Engineer (FAE) teams provide 24/7 technical consultation and troubleshooting. Customer complaint teams respond swiftly to product anomalies, delivering effective solutions within one hour.

- Continuous Improvement: We analyse after-sales feedback, test data, and real-world usage scenarios to continually refine product design, materials, and manufacturing processes, achieving iterative quality upgrades.

Authoritative certification: Quality recognised worldwide

Our smart wearable devices have earned recognition from leading global brands, including community healthcare providers, care homes, health technology companies, and cross-border e-commerce brands. Partner with us to deliver reliable health monitoring solutions for your customers.

Smartwatch Complete Certification